Top natural pest control methods for a healthy garden

- By Raw Michelle - April 28, 2014

By now, people are well aware of the dangers behind eating foods that have been treated with pesticides. The Centers for Disease Control and Prevention (CDC) states that approximately 1.1 billion pounds of pesticide active ingredients are used annually in the U.S., and the EPA says up to 20,000 U.S. agricultural workers are diagnosed with pesticide poisonings annually.

By now, people are well aware of the dangers behind eating foods that have been treated with pesticides. The Centers for Disease Control and Prevention (CDC) states that approximately 1.1 billion pounds of pesticide active ingredients are used annually in the U.S., and the EPA says up to 20,000 U.S. agricultural workers are diagnosed with pesticide poisonings annually.

Choosing organic produce at the market and even growing fruits and vegetables in the backyard are safe and favorable options. However, when growing foods in the yard, there's often the matter of having to fend off pesky intruders that chomp away at foods and even harm the entire crop with disease.

Here are some ways to safely grow foods in the yard.

Natural ways to ward off garden pests

1 - Plant marigolds. They emit an odor that many pests avoid and is the reason many gardeners plant them around the perimeter of gardens.

2 - Buy ladybugs. Many garden centers have ladybugs in bulk which can be purchased as a natural aphid controller.

3 - Create homemade concoctions. Many gardeners have been successfully maintaining their home-grown produce by turning to homemade, natural pesticides. For example, a mixture of Himalayan salt and a gallon of warm water can treat areas infested with spider mites when sprayed on the areas in question. If ants are a concern, break out citrus essential oil and combine it with a teaspoon of cayenne pepper and one cup of warm water. Then shake the mixture and spray.

4 - Consider hanging a bat house. Forget the scenes from scary movies. Bats don't harm people and since they can devour hundreds of kinds of insects every hour, they're good to have around. Be sure to hang the bat house at least 15 feet from the ground in a location that receives at least six hours of sunlight daily.

5 - Plant peonies. Not only do they look pretty, but they attract a wasp that eats the larvae of grubs.

Natural methods like these are a safe way to keep pests away from the garden so people can enjoy fresh foods without exposure to pesticides.

Sources for this article include:

http://www.cdc.gov/niosh/topics/pesticides/

About the author:

Raw Michelle is a natural health blogger and researcher, sharing her passions with others, using the Internet as her medium. She discusses topics in a straight forward way in hopes to help people from all walks of life achieve optimal health and well-being. She has authored and published hundreds of articles on topics such as the raw food diet and green living in general.

3 plus 25 amazing reasons to add lemon to your water

- By Jeanette Padilla - April 27, 2014

Lemons have a plethora of positive health benefits. They are packed with vitamin C, B-complex vitamins, potassium, iron, calcium and magnesium. To reap the health benefits of lemons simply add them to your water. Lemon juice can potentially wear down tooth enamel. In order to avoid this problem, simply dilute the lemon juice with lukewarm water.

Lemons have a plethora of positive health benefits. They are packed with vitamin C, B-complex vitamins, potassium, iron, calcium and magnesium. To reap the health benefits of lemons simply add them to your water. Lemon juice can potentially wear down tooth enamel. In order to avoid this problem, simply dilute the lemon juice with lukewarm water.

Lose weight

One reason to add lemon juice to you water is to lose weight. Pectin fiber, present in lemons, helps fight hunger cravings. Lemon juice is also a digestive aid. It encourages the production of bile, which is what breaks down food during digestion. Drinking lemon water can also help keep your liver clean. This is important because the liver metabolizes fat and secretes bile. Together, these small advantages can help you lose weight over time.

Boost your immune system

Drinking lemon water can also help keep your immune system strong. Due to its antibacterial properties, drinking lemon water can help soothe a sore throat. Lemon water is a great support to the lymphatic system, which works in conjunction with your immune system to trap and eliminate pathogens. Lemon water helps cleanse the lymph stored by the nodes of the lymphatic system. Lymph is basically a collection of "garbage" collected from the body.

Reduce inflammation

Good news for those who suffer from inflammation. Adding lemon juice to your water can help significantly reduce inflammation. Lemons have anti-inflammatory properties. They also help neutralize acidity which is the main cause of tissue inflammation. Lemon juice is acidic outside of the body but once metabolized, it becomes alkaline. Alkalinity reduces acidity and thus, reduces inflammation.

Whether adding lemon wedges or pure lemon juice to your water, make sure to use organic non-GMO lemons. Stay away from lemon juice concentrate that is sold in stores. These pre-bottled juices contain preservatives and other additives that have negative effects on the body. Processing during manufacturing eliminates natural enzymes, vitamins and antioxidants found in lemon juice, for this reason, it's best to use natural, fresh-squeezed lemons.

Start by using 1/4 of a lemon (juice) in an 8-ounce cup of water. Work your way to one lemon per 8 ounces. It's typical that the lemon water will taste bitter or sour when you first start out. After a few days you may notice the lemon water taste sweet, like lemonade. This is just your body's pH level adjusting and become less acidic.

Sources for this article include:

25 plus 3 Health Benefits of Lemons – Quick and Easy Way to a Healthier Body

- By Jeanette Padilla

Among the most commonly known therapeutic properties for lemons are its uses for throat infections, pH balance and indigestion. But the health benefits of lemons don’t stop there. You’ve used them to make lemonade or perhaps squeezed them over grilled chicken to give it a zesty kick, but did you know that lemons have numerous health benefits? If you’ve ever asked yourself “what do lemons do for your body?”, you’re about to find out and you’ll never go without having at least a few on hand.

The Many Health Benefits of Lemons

Lemons contain significant amounts of vitamin C and potassium. Lemons also have antioxidant properties which make them great for cleansing and fighting disease. The juice of a lemon can help with indigestion; it’s citric acid content helps aid digestion. Lemon juice is also helpful in overcoming a fever, a cold or the flu. It’s antibacterial properties fight pathogens and it’s cleansing properties help purify the blood from unwanted toxins. Lemon’s cleansing properties make it a powerful aid to the lymphatic and immune systems. Lemon juice can also be used in skin care, dental care, hair care, arthritis, pH balance, weight loss, nausea, vomiting, mineral replenishment, high blood pressure, inflammation and respiratory problems.

Are Lemons Acidic or Alkaline?

Everyone knows lemons are sour and therefore, they are considered to be acidic. This is true. However, they are also alkaline. To be more precise we should say they are alkaline forming. Lemon’s citric acid makes it acidic but it’s overall nutrients such as it’s minerals: calcium, magnesium, potassium and selenium are alkaline. Citric acid is a “weak” acid. This means that it is easily eliminated by the body once it has done its job. Once metabolized, citric acid stimulates the formation of calcium carbonate which is alkaline. Calcium carbonate then neutralized “strong” acids such as uric acid. Ridding the body of uric acid and other “strong” acids is of great importance. A body that is too acidic can lead to conditions such as gout, diabetes, ulcers, obesity, arthritis and osteoporosis, to name a few.

Lemons for Dental, Skin & Hair Care

Lemon juice mixed with water and baking soda can be used to naturally and gradually whiten teeth. Try mixing 1 part lemon juice, 3 parts water a dash of baking soda and brush your teeth with it to naturally help whiten your teeth. To help eliminate bad breath mix equal parts lemon juice and water. Use this mixture as mouthwash whenever you need to naturally eliminate bad breath. If you’re looking for a naturally remedy for gingivitis try mixing 1 part water, 1 part lemon juice and 1 part apple cider vinegar. Use this mixture as a mouthwash once a day. You will see both gum inflammation and bad breath gradually desist. You may have heard of the dangers of using lemon juice on you teeth due to its ability to damage the enamel. This is not necessarily true. If you suck on lemons all day and constantly expose lemons to your teeth then yes, this is possible. However, drinking lemon water does not expose your teeth to excessive levels of citric acid for a prolonged period of time so the enamel should not be harmed.

Here are some natural tricks for better skin you’ll want to try out immediately! Did you know you can use lemon juice to help eliminate pimples and zits. Simply take a sterile cotton pad, drop 5-10 drops of lemon juice on it (you can also quickly dip the pad in lemon juice) and swipe it across the areas you’d like to treat. Make sure you apply the lemon juice to clean skin, perhaps try this when you first wake up in the morning and before going to bed after you’ve washed your face. Leave the lemon juice on for 10 minutes then rinse off and pat try. Lemon juice can also help lighten dark spots caused by acne scars. Simply apply the lemon juice onto clean skin in the affected area, wait 10 minutes and rinse off. If the treated area is going to be exposed to sunlight soon after, make sure to use proper SPF. For tougher spots like blackheads (and whiteheads) you can use a mix of lemon juice, packed brown sugar and raw honey to exfoliate with. This natural exfoliator will help draw out black heads.

Hair and lemon juice have a couple of well kept beauty secrets. Did you know you can use lemon juice to help eliminate dandruff? Squeeze out the juice of 1 lemon, this should yield about 3 tablespoons. Take approximately 2 tablespoons of warm coconut oil (heat briefly in the oven in an oven safe dish such as a ramekin) and mix in the lemon juice. Check the temperature of the mix to be safe not to burn your scalp. Apply the mixture all over the scalp using a clean cotton swab. Leave on for up to 20 minutes then rinse off. Shampoo as needed afterwards. The anti-fungal and antibacterial properties of both lemon juice and coconut oil help eliminate the fungus that causes dandruff. Use this remedy 2 or 3 times a week as needed.

A more widely known hair care beauty tip is the use of lemon juice to naturally lighten hair. Apply lemon juice to select stands of hair you wish to lighten. You can do this by squeezing out the lemon juice, straining it through a fine sieve and pouring it into a spray bottle. Mix in an equal part of water. Once both water and lemon juice are in the spray bottle, lightly dampen the selected strands. Remember the more you soak your hair with this mixture the lighter it will get. Go out in the sun to let the lemon juice react with sunlight, this reaction will lighten your hair. The longer you stay in the sun the lighter your hair will get. Use caution and wear the appropriate level of sunscreen depending on how long you will be out in the sun. When using this method it is very important that you do not overdo it and stay out in the sun excessively; doing so can dry out and damage your hair. A healthy amount of time in the sun for natural highlights would be about 20 minutes a day.

Lastly, if you’re looking for a way to naturally strengthen brittle nails try lemon juice. Mix equal parts extra virgin olive oil with lemon juice and rub onto your fingernails covering from cuticle to tip. This will not only condition and strengthen your nail but it’s also an excellent way to naturally whiten yellowing fingernails. After 20 minutes or so rinse your hands and wash them thoroughly with soap. You can repeat this process 2-3 times a week until your nails are stronger and healthier.

The Many Benefits of Lemon Water

The best way to receive all of the benefits of lemons is to drink lemon juice in water. The best way to do this is by squeezing fresh organic non-GMO lemons. You can buy lemon juice already squeezed but those store bought bottles of lemon juice tend to have added ingredients that are not so healthy for you. It’s best to do it yourself and it’s easy and quick to do. The amount of lemon juice per glass of water depends on each individuals particular preference. We recommend half a lemon (roughly 3 tablespoons) per 8oz of water. You can start with this ratio and gradually work your way to a whole lemon per 8oz of water. For best results it is recommended that you use warm or room temperature water. The reason for this is it takes the body time and energy to bring cold water up to body temperature so this natural remedy will be more effective if warm water is used.

Don’t worry if you find the taste of lemon water too sour when you first begin. Especially if you’re only using 1-2 tablespoons of lemon per 8oz water. The sour taste of lemon water will gradually fade as your body becomes more alkaline. In fact, as you continue to drink lemon water it will eventually taste sweet (like lemonade without the sugar), that is a sign your body is alkaline. Also, please keep in mind that lemon juice is a powerful cleanser. For this reason it is best to listen to your body. The best way to cleanse in a healthy and safe manner is to start out slowly and let your body acclimate to changes in diet. If you find that half a lemon in 8oz of water is too much for you try using a quarter of a lemon then work your way up to a half. Drink 2-3 glasses of lemon water along with 5-6 glasses of plain water a day for best results.

Lemons & Nausea

Traveling can be such fun and exciting experience. This however, is not the case for those that suffer from car sickness, sea sickness and general motion sickness when traveling; especially when traveling long distances. Remember this trick and you’ll won’t have to suffer from motion sickness anymore. Mix a little bit of lemon juice into a bottle of water and add a hint of salt. Drink this on the way to your destination to prevent motion sickness.

If you can’t take a bottle of water with you, don’t worry. Lemons are easily available nearly everywhere so you can create this natural remedy for motion sickness on the fly. For children, you can add in a bit of honey to lessen the sourness and make it easier for them to drink. It’s basically lemonade but it’s important that you use honey instead of sugar because honey also has healing properties. Drinking lemon water also aids nausea and vomiting because of its mineral content. It not only settles the stomach but will help kill unfriendly bacteria causing nausea and will help replenish lost minerals in the case of vomiting

Lemons & Weight Loss

Warm water and lemon juice has to be one of the easiest and most beneficial thing you can do for your health and waistline. Lemons contain high levels of vitamin C which increase liver function and metabolism. Increasing liver function is important because the liver perfumes many important and critical functions such as creating bile for digestion. A healthy liver can also greatly support rapid weight loss in a healthy manner through it’s role in metabolizing fats, carbs and proteins. Lemon water can also help decrease low-density lipoprotein also known as bad cholesterol. If taking lemon water for weight loss its best to drink it first thing in the morning before eating breakfast. This will help cut through fat and reduce cellulite.

Drinking lemon water can also help curb sugar cravings which is especially helpful because sugary foods create an acidic environment in the body. The alkalizing properties of lemons also neutralize acidity, which can lead to rapid weight loss. Lemons are also a diuretic and help support kidney function. This is especially helpful for when trying to eliminate bloating and water retention. Drinking warm lemon water also aids digestion and soothes the stomach, remember this little tip next time you have a big meal and need help digesting!

Lemons & Inflammation

We previously discussed the alkalizing nature of lemons. Lemon’s ability to neutralize acid as well as to create a more alkaline environment for tissue is greatly under-appreciated. Acidity in the body can lead to inflammation, even chronic inflammation in some cases. A diet high in refined sugars, stress and medications are some of the largest contributing factors to high levels of acidity in the body. The anti-inflammatory properties of lemons can help eliminate inflammatory diseases such as: gout, arthritis, atherosclerosis, ulcerative colitis, diverticulitis, dermatitis, Crohn’s disease, vasculitis, hepatitis and respiratory disorders. Lemon can cut through phlegm. Keep this in mind next time you have congestion in the lungs or sinuses.

Lemons & the Lymphatic System

The lymphatic system’s job is to trap and eliminate pathogens and toxins from the body. Once trapped, these toxins are kept in lymph nodes until they are pushed out of the body by the lymphatic system. This system works with the circulatory and immune systems to keep the body healthy and clear of disease. Lemon’s anti-bacterial, anti-fungal and anti-viral properties not only help the lymphatic system by combating pathogens they also help cleanse the lymph nodes. Lemon water also stimulates the lymphatic system to remove toxins from the colon and bladder.

Lemons & the Urinary System

The urinary system is in charge of flushing uric acid out of the body through urination. When this is not occurring regularly, high levels of uric acid in the bloodstream form into sharp crystals that settle in the joints; this is called gout. This pesky ailment can range from mild sharp pains in the joints, predominately felt in the fingers and toes, to severe, life-threatening cases. Drinking warm lemon water can help dissolve uric acid crystals and even provide immediate relief from gout pain.

According to studies from the American Urological Association, lemon juice can prevent the formation of kidney stones. The studies reveal that lemon juice can create urinary citrate, which prevents the formation of kidney stones. The anti-inflammatory and anti-bacterial properties of lemons also help keep the urinary tract free from bacteria and inflammation. Lemons juice can also be used to naturally eliminate kidney stones. Mix the juice of half a lemon with 8 oz of water. Drink one glass every two hours for an entire day. The lemon juice will help dissolve kidney stones so they can exit the body in a pain-free way. Doing this will also reduce inflammation and lessen the pain of passing kidney stones. For best results, while eliminating kidney stones, stay away from foods such as: refined sugars, processed beverages, carbs, and red meat. Eat foods that will be easy to digest and will not add to the detox load.

Lemons & Gallstones

The gallbladder plays a very important role in digestion by storing and secreting bile for digestion. Bile stored in the gallbladder can harden and become gall stones. Gallstones also form from poor digestion and the excess consumption bad fats. Lemon juice can be used to remove gallstones. Drink 2 oz of lemon juice and lay on your right side for 15 minutes. Then drink 2 oz of extra virgin olive oil and a bit more lemon juice to clear the taste of oil from your palate. Lay on your right side for at least 2 hours. This natural remedy for gallstones is best done before going to bed. It’s important that you keep as light a diet as possible before implementing this remedy. Afterwards, be sure to continue eating lightly and clean to give your gallbladder the opportunity to keep cleansing. Lemons also serve as blood purifiers and help the liver by removing the build up of toxins filtered from the blood. This is important because the liver and gallbladder work in synergy.

Lemons for Home Use

Next time you buy a sack of lemons try out these naturally cleaning remedies. You can use lemons to treat stains in white clothing and linens. Adding the juice of one lemon (without the seeds) to a load of whites will help naturally whiten your clothes. This trick will also help kill bacteria and deodorize your clothes; plus you get the additional bonus of clean, lemon-scented clothing! Thin slices of lemon can also help deodorize the kitchen sink. Simply toss a 2-3 thin slices in the disposal and run some hot water with the disposal on for a 10 seconds. The smell of fresh lemons will instantly envelop your kitchen and rid the disposal of any foul smells.

Do you want that fresh, clean, lemony scent in your kitchen without using chemical cleaners? You can get that lovely scent while sanitizing your kitchen. You can make a spray bottle of natural cleaning fluid to clean and disinfect with the added bonus of that invigorating lemony scent. For the spray bottle: combine the juice of 2 lemons (filtered to remove seeds and lumps), this will yield about 6 tablespoons or just over 1/3 cup, with 2 cups of water (16 oz), and any essential oil of your choice. I like to use a specific blend of the oils lavender, tea tree and eucalyptus from NSP; I’ll tell you why in a moment. Use about 10 drops of each. Pour the lemon juice, water and oils into the spray bottle and shake vigorously. Once blended you can use this mix to clean kitchen & bathroom counter tops as well as other surfaces.

This blend will not only make your house smell great but the anti-bacterial properties of the lemon juice and all of the oils will disinfect counter and any other surface you use it on. If you use the blend of lavender, tee tree and eucalyptus you get the added bonus of repelling insects. You can spray this mixture lightly around carpeted areas, window and door openings to keep bugs out. This blend is not recommended for wooden surfaces as the oils can damage the wood. For best results test on a small, unnoticeable spot.

If you’re in a bind and you need to quickly and naturally deodorize your house why not knock out two birds with one stone? Cut a lemon in half and use the open face side of each lemon to “scrub” the kitchen counters and the stove top. Then simply wipe down all the “scrubbed” surfaces with a moist paper towel and you’re done! Your kitchen will smell better and your counters will be clean! You can also use the lemon slices in the garbage disposal trick for an added dose of lemony scent. Another good trick to remember, you can use the open face of a lemon halve to scrub a cutting board. Go with the grain when scrubbing to preserve the wood then rinse with warm water. This will help disinfect the cutting board and leave a lovely, clean lingering scent.

Disclaimer: Our services and information do not diagnose or prescribe for disease conditions. Individuals are encouraged to seek competent medical help when those services may be indicated. Individuals accept total responsibility for their own health care and maintenance.

Reference:

http://www.huffingtonpost.com/2013/08/13/lemon-beauty-benefits_n_3743905.html

http://www.doctoroz.com/videos/health-benefits-lemons

http://nutritiondata.self.com/

http://www.vitalitylink.com/article-holistic-health-2055-lemon-juice-acidic-alkaline-body-water

http://www.innerbody.com/image_digeov/card10-new2.html

About the author:

Jeanette Padilla is an experienced herbalist and iridologist. Read more health articles from her at Sunshine Natural Healing

Celebrate For Change - The Dawn of a New Era

A Silent Revolution / Evolution, The Best Form of Civil Disobedience

- By Bahram Maskanian

On March 21, stay home all day and night and celebrate LIFE - a necessary and effective paradigm shift, an exercise in national unity and cooperation.

On March 21, stay home all day and night and celebrate LIFE - a necessary and effective paradigm shift, an exercise in national unity and cooperation.

Let us celebrate liberty, justice, happiness and true democracy, by staying home all day, cooking and enjoying good healthy foods, vegetables and fruits, dancing, singing, laughing and truly celebrating LIFE on March 21. Let it be known, that from this day forward, it shall be recorded in world history, the first day of spring, March 21st as the “NEW DAY”, and as the day of festivity and national holiday, it shall be celebrated each and every year.

To celebrate is to physically mark an important happy occasion, in order to express one’s appreciations. To celebrate is to be thankful to Mother Nature for all that she has provided for all of humanity and bestowed upon all of us. To celebrate is to recognize our common deep desires for liberty, justice, happiness and our abilities to bring about positive changes impacting humanity for better, through positive and uplifting powers of celebration.

We could also celebrate for change, the necessary changes we must make, if we hope to survive on planet Earth as human species. Protesting our disapproval and discontent of the criminal ruling elites through celebration. You see, political demonstrations have never been effective, the ruling elites simply waits people out, and after the demonstrators are gone home, they continue doing what they want. “Those who do not learn from their history are doomed to repeat it.”

Therefore, I would like to invite my fellow Americans to celebrate LIFE, returning to our one and only home planet Earth, in show of solidarity as a united people, by staying home all day, thus demonstrating our strong will for change, on March 21, the “NEW DAY”, marking the beginning of the dawn of a new era, the day of festivity, celebrating: liberty, justice, happiness, human rights, life and Mother Nature.

It must be noted that, due to the relentless dumbing-down efforts of the public by the criminal elites in the past 50 years, some folks are under a misguided impression that consumption of alcohol and drugs coupled with loud and idiotic manners, ruining one’s health, throwing away one’s hard earned cash, killing one’s brain, heart, kidneys, liver and stomach causing violent and stupid behavior, altering one’s character and personality for worse, is actually celebrating.

Prior to the invention of Christmas, a majority of the people all over the world celebrated the return of life back to planet Earth on 21st of March, the first day of Spring. People all over the world celebrated the four seasons, each month of the year; the sun, rain, soil and generally all life sustaining and enhancing elements on Earth were celebrated.

Christmas celebration was invented less than 200 years ago, by the 19th-century literary figures such as: C. S. Lewis, Washington Irving, Clement Clarke Moore, and of course, Charles Dickens. History has revealed that Christian, or pagan Christmas is a Victorian fabrication and nothing more.

Also read: The American Peoples' Command Directive

Woody Harrelson Shares Powerful Thoughts

Deadly MERS virus spreading out of control in Saudi Arabia, leaps to Egypt as global pandemic begins

- By Mike Adams, the Health Ranger, Editor of NaturalNews.com - April 26, 2014

It has long been recognized by intelligent observers that a global superbug pandemic is inevitable. Humanity has created the perfect conditions for it: global nutritional deficiencies, weakened immune systems, high population density, high-speed international travel and systemic abuse of antibiotics by medical professionals. Drug-resistant superbugs like MERS (Middle East Respiratory Syndrome) are 100% immune to every conventional medical treatment in existence. There is no antibiotic, no vaccine, no drug and no treatment practiced by western medicine that can stop these bugs... and infections are deadly.

It has long been recognized by intelligent observers that a global superbug pandemic is inevitable. Humanity has created the perfect conditions for it: global nutritional deficiencies, weakened immune systems, high population density, high-speed international travel and systemic abuse of antibiotics by medical professionals. Drug-resistant superbugs like MERS (Middle East Respiratory Syndrome) are 100% immune to every conventional medical treatment in existence. There is no antibiotic, no vaccine, no drug and no treatment practiced by western medicine that can stop these bugs... and infections are deadly.

Now we've learned they're spreading out of control in Saudi Arabia, following an explosive pandemic pattern that has infectious disease experts sounding the alarm.

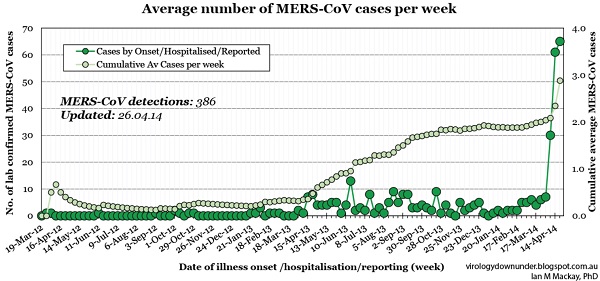

Ian MacKay, an associate professor at the Australia Infectious Diseases Research Centre at The University of Queensland, is now warning about where this might be headed. Over the last 30 days, MERS cases in Saudi Arabia have exploded from just 1-3 per day to over 10 per day, showing a worrisome trend.(1)

"MERS is a particularly nasty disease for those who already have a disease that is chronic," writes Ian MacKay on his blog. (2) "These include diabetes, kidney disease, heart disease, hypertension, lung disease, obesity, malignancy and those who smoke or use steroids."

An alarming 140 cases have been found in April alone, and more MERS cases have been reported so far in 2014 than during the entire year of 2013.

The following chart shows an alarming trend in the cumulative number of MERS infections with a sharp spike in cases being reported in mid-April:

Healthcare workers increasingly infected: 7% death rate reported

According to data analysis by MacKay, healthcare workers are also being infected and an astonishing 7% are dying from those infections. From MacKay's blog: (2)

Healthcare worker (HCW) numbers have risen sharply (see below) during the April outbreak to a total of 84 detections, 7% of whom have died. Deaths (left) among HCWs now represent 1.6% of all MERS-CoV positive deaths. This jump in HCW detections has been fuelled by the Jeddah outbreak but also by the parallel HCW cluster among paramedics in the UAE; two as yet completely unexplained events.

When healthcare workers are infected, they tend to increase the spread of the disease by inadvertently infecting patients. This is why hospitals can quickly become extremely dangerous places during any outbreak: it's where you're mostly likely to get infected. Hospitals, in essence, become hubs that spread the disease and multiply the pandemic. This is exactly what has been observed in Ebola outbreaks, by the way.

MERS has now spread to Egypt

The LA Times(3) is now reporting that MERS has spread from Saudi Arabia to Egypt:

State television said Saturday that the country's first case had been discovered. It said the patient, who was hospitalized in Cairo, had recently traveled to Saudi Arabia, where the virus was first identified.

So now we have the first documented case of MERS crossing borders and becoming an international superbug. It's only a matter of time before visitors to Saudi Arabia carry this superbug to other nations as well.

Western medicine is utterly helpless against MERS

What's especially alarming about the spread of MERS is that all the tools of western medicine -- drugs, vaccines, surgery -- are completely and utterly useless against MERS and many other superbugs.

So when patients get infected and go to the hospital, those hospitals have nothing to offer them except, perhaps, exposure to other superbugs that are now running rampant across hospitals. Half of all hospital rooms are infected with superbugs, and superbugs are now killing 48,000 patients a year in the USA alone. Deadly superbugs are even sweeping California hospitals and nursing homes.

Western medicine hospitals are beholden to drug company interests, so they refuse to recognize or prescribe treatments that aren't patented by drug companies. This means hospitals will refuse to prescribe herbal treatments that can block MERS infections such as the "Minor Blue Green Dragon" formula which contains a highly effective anti-pandemic ingredient that has been outlawed by the FDA.

Western medicine will kill millions in the next pandemic

As this infection spreads globally, people who rely solely on Western medicine will die en masse, victims of a system of medicine which oppresses and even outlaws competing systems of medicine that offer far more effective solutions for pandemic defense. Those who embrace more diverse systems of medicine (such as Traditional Chinese Medicine) will have anti-pandemic remedies readily available. These remedies actually contain powerful medicinal compounds which have been synthesized by plants rather than by laboratories. Anyone who discounts the power of natural herbal medicine is flatly ignorant: as much as 25% of Big Pharma's drugs are originally derived from medicinal plants in the first place (then modified to be patentable). Statin drugs, for example, were modeled after the natural lovastatins originally discovered in red yeast rice.

As the next global pandemic spreads, western medicine's monopolistic rejection of natural remedies will almost certainly result in the deaths of potentially millions of victims -- people who could have been saved if they had only been told the truth about non-pharmaceutical treatments against infectious respiratory illnesses. It's absolutely criminal that when western medical professionals have literally nothing to offer for a deadly superbug, they simultaneously don't want people to have access to anything else that might work either. Their message? "Go home and die, but don't you dare take herbal medicine because that might be dangerous."

I'm not saying that a person shouldn't use western medicine in a pandemic, by the way. My advice is to use every tool you can find -- western medicine, eastern medicine, herbal medicine, nutritional therapies, sunlight therapy, etc. Only a fool limits his options to the one single system of medicine that offers zero solutions.

Sources for this article include:

(1) http://www.buzzfeed.com/sheerafrenkel/a-dead...